Static Mixers

Price 45 INR/ Piece

Static Mixers Specification

- Product Type

- Static Mixer

- General Use

- Industrial liquid and gas mixing

- Material

- Stainless Steel

- Type

- Inline Mixer

- Capacity

- Customizable based on application

- Weight (kg)

- Depends on model and length

- Computerized

- No

- Automatic

- Optional

- Control System

- Manual

- Function

- Mixing and blending of fluids

- Working Temperature

- Up to 120C

- Dimension (L*W*H)

- Customized as per requirement

- Feature

- Low maintenance, high efficiency

- Color

- Metallic Silver

Static Mixers Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 200 Pieces Per Week

- Delivery Time

- 1 Week

About Static Mixers

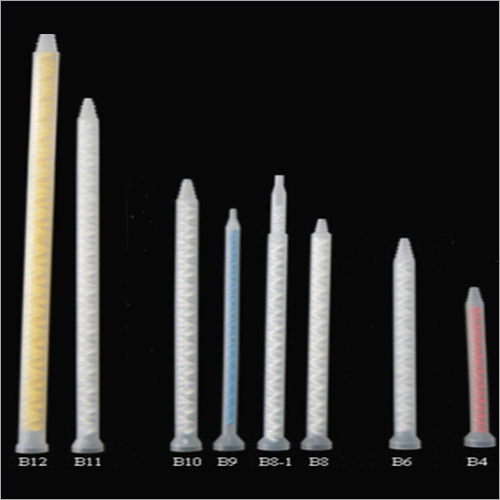

Based in Pune, Maharashtra, we are one of the eminent companies engaged in supplying Static Mixers. They are a type of precision engineered devices that are required for mixing fluids, dispersed gases into liquid, and for mixing gas streams. These mixers work on continuous mixing principle whereas energy required comes from loss in pressure when fluid flow through assembly. Static Mixers offered by us can be availed in different length and diameter sizes as required according to need.

Features:

- High quality polypropylene made tube

- Helical mixing element is made of glass-lined steel

- Ideal to be used for epoxy resins and sealants

Product details

|

Length |

2-15 inch |

|

Brand |

Amspa |

|

Sizes |

1/2"- 20" |

|

Capacity |

5-100 m3 / h |

|

Length |

2-15 inch |

|

Brand |

Amspa |

|

Sizes |

1/2"- 20" |

|

Capacity |

5-100 m3 / h |

Superior Mixing Efficiency

Equipped with advanced helical and blade elements, our static mixers utilize both turbulent and laminar flow principles to ensure thorough and homogeneous mixing. Suitable for liquids and gases, these units deliver consistent results even with high-viscosity fluids.

Versatile Installation Options

Thanks to their inline mounting design, our static mixers can be installed horizontally or vertically to meet diverse process requirements. Standard flanged or threaded connections (DIN, ANSI) and customizable dimensions make integration into existing systems seamless.

Robust Construction and Easy Maintenance

Built from high-grade stainless steel (SS304/SS316), our mixers resist corrosion in demanding environments. Their low maintenance and CIP-compatible design simplify cleaning and prolong equipment lifespan, reducing operational downtime.

FAQs of Static Mixers:

Q: How are static mixers installed in an industrial system?

A: Static mixers are designed for easy inline installation using flanged or threaded DIN or ANSI connections. They can be mounted horizontally or vertically, allowing flexibility to adapt to various piping layouts and process configurations.Q: What applications are static mixers suitable for?

A: These mixers are ideal for chemical processing, water treatment, pharmaceuticals, food and beverage production, and other industrial fluid and gas mixing tasks. Their ability to handle different viscosities makes them versatile for a wide application range.Q: When should I use a static mixer over a dynamic mixer?

A: Static mixers are preferred when maintenance needs to be minimal, a consistent blend is required, and power or moving parts are undesirable. They are especially beneficial in continuous flow processes and where CIP cleaning is important.Q: Where can these mixers be sourced or customized in India?

A: We are importers, manufacturers, and suppliers offering ready stock or made-to-order inline static mixers in India. Custom sizes and features are available to meet your specific process requirements.Q: What is the cleaning process for static mixers?

A: Static mixers are compatible with Clean-in-Place (CIP) systems, enabling straightforward and effective internal cleaning without the need for disassembly. This ensures hygiene standards are maintained, especially in sensitive applications.Q: How do static mixers handle fluids with varying viscosities?

A: With robust SS304/SS316 elements and advanced mixing principles, our mixers efficiently process low to high viscosity fluids, ensuring uniform blending even when dealing with challenging substances.Q: What are the benefits of using corrosion-resistant elements in static mixers?

A: Corrosion-resistant stainless steel elements enhance durability, minimize maintenance, and ensure reliable operation under harsh chemical or high-moisture conditions, safeguarding long-term mixer performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dispensing Equipment Category

Adhesive Barrel End Caps

Price 15 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Manual

Computerized : No

General Use : Industrial, Packaging, Adhesive Dispensing

Type : End Cap

Adhesive Syringe Barrel

Price 35.00 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, Manual or Pneumatic

Computerized : No

General Use : Adhesive dispensing in industrial applications

Type : Adhesive Dispensing Accessory

Dispensing Needles

Price 350 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Manual

Computerized : No

General Use : Fluid, Glue and Liquid Dispensing

Type : Industrial, Laboratory

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry