Adhesive Barrel End Caps

Price 15 INR/ Piece

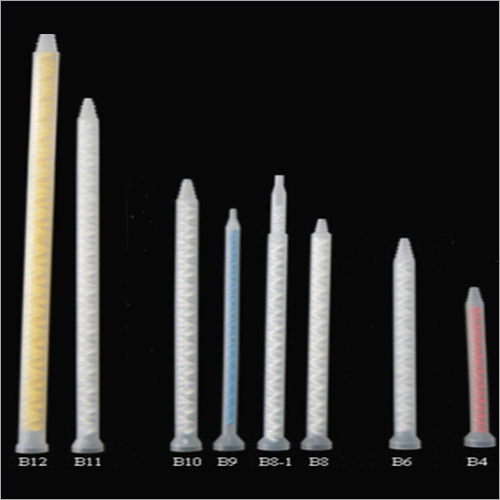

Adhesive Barrel End Caps Specification

- Product Type

- Adhesive Barrel End Caps

- General Use

- Industrial, Packaging, Adhesive Dispensing

- Material

- Plastic (Polyethylene or Polypropylene)

- Type

- End Cap

- Capacity

- Fits standard adhesive barrels (3cc, 5cc, 10cc, 30cc, 55cc, etc.)

- Weight (kg)

- ~0.002 (per cap)

- Computerized

- No

- Automatic

- No

- Control System

- Manual

- Function

- Sealing and protecting ends of adhesive barrels

- Working Temperature

- -10C to 80C

- Dimension (L*W*H)

- Depends on barrel size (commonly 18mm diameter x 14mm length for 30cc barrel)

- Feature

- Leakproof, Snap fit, Reusable, Chemical resistant

- Color

- White, Natural, or Custom

Adhesive Barrel End Caps Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 200 Pieces Per Week

- Delivery Time

- 1 Week

About Adhesive Barrel End Caps

Backed by our diligent professionals, we are one of the trusted suppliers of Adhesive Barrel End Caps. They are made of high grade thermoplastic polymer for having resistance to various chemicals used in glue formulation. These barrels & end caps are required for filling small amount of adhesive to assure easy application and prevent spilling. Adhesive Barrel End Caps offered by us can be availed in different sizes and structural configurations as demanded by clients.

Features:

- Light in weight

- Highly durable

- Supports easy tip attachment

Product details

|

Cap Type |

Seal Caps |

|

Neck Size |

10-20 mm, 60, 40-50 mm, 30-40 mm, 20-30 mm |

|

Packaging Type |

Box |

|

Material |

LDPE |

|

Brand |

Amspa |

Superior Sealing Performance

The end caps offer leakproof and secure sealing for adhesive barrels, ensuring that adhesives and fluids are properly contained. Their snap-fit design enhances grip, making installation and removal quick and effortless while maintaining a tight seal.

Durable and Chemical Resistant

Crafted from high-quality polyethylene or polypropylene, these end caps are resilient against chemical corrosion and physical wear. Designed to withstand repeated use, they retain their shape and functionality across a spectrum of industrial environments.

Versatility Across Applications

Compatible with most standard barrel sizes, end caps serve various industrial purposes including adhesive dispensing, packaging, and fluid containment. Their reusable nature aids in reducing waste while supporting continuous operations.

FAQs of Adhesive Barrel End Caps:

Q: How do I install the Adhesive Barrel End Caps?

A: Simply align the round cap with the end of your adhesive barrel and press gently until the snap fit mechanism securely locks in place. The grip tab assists with easy installation and removal by hand, eliminating the need for tools.Q: What types of barrels are compatible with these end caps?

A: These end caps are designed to fit most standard adhesive barrel types, including sizes such as 3cc, 5cc, 10cc, 30cc, and 55cc, making them versatile for a broad range of dispensing applications.Q: When should I replace or reuse the end caps?

A: Since the end caps are reusable and constructed from durable, chemical-resistant materials, you should replace them only if they show signs of wear, damage, or loss of sealing efficiency after repeated use.Q: Where are these end caps typically used?

A: Adhesive Barrel End Caps are commonly used across industrial settings, in adhesive dispensing stations, packaging lines, and for ink or fluid containment tasks, especially where leakproof and secure sealing is essential.Q: What is the process for cleaning and maintaining these reusable caps?

A: To maintain optimal performance, rinse the caps with a compatible cleaning solution appropriate for your adhesive or fluid type. Allow them to thoroughly dry before reuse, ensuring no residue or debris remains on the sealing surfaces.Q: What are the main benefits of using these end caps?

A: The main advantages include reliable leakproof sealing, chemical resistance, easy manual handling thanks to the grip tab, reusability, and compatibility with a variety of barrel sizes. This reduces cost and waste in industrial processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dispensing Equipment Category

Static Mixers

Price 45 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Manual

Working Temperature : Up to 120C

General Use : Industrial liquid and gas mixing

Weight (kg) : Depends on model and length

Dispensing Needles

Price 350 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Manual

Working Temperature : 20C to 80C

General Use : Fluid, Glue and Liquid Dispensing

Weight (kg) : 0.002 0.01

Adhesive Syringe Barrel

Price 35.00 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : Other, Manual or Pneumatic

Working Temperature : 20C to 60C

General Use : Adhesive dispensing in industrial applications

Weight (kg) : Approximately 0.010.05 kg (depending on size)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry